Views: 642 Author: Site Editor Publish Time: 2025-03-01 Origin: Site

Content Menu

● How low the temperature is,that PEEK can still withstand it?

● PEEK's high temperature resistance is one of its major features.

● PEEK material has further improved its high temperature resistance after fiber-reinforced

>> Thermal Properties of Fiberglass Reinforced PEEK

>> Thermal properties of carbon fiber reinforced PEEK

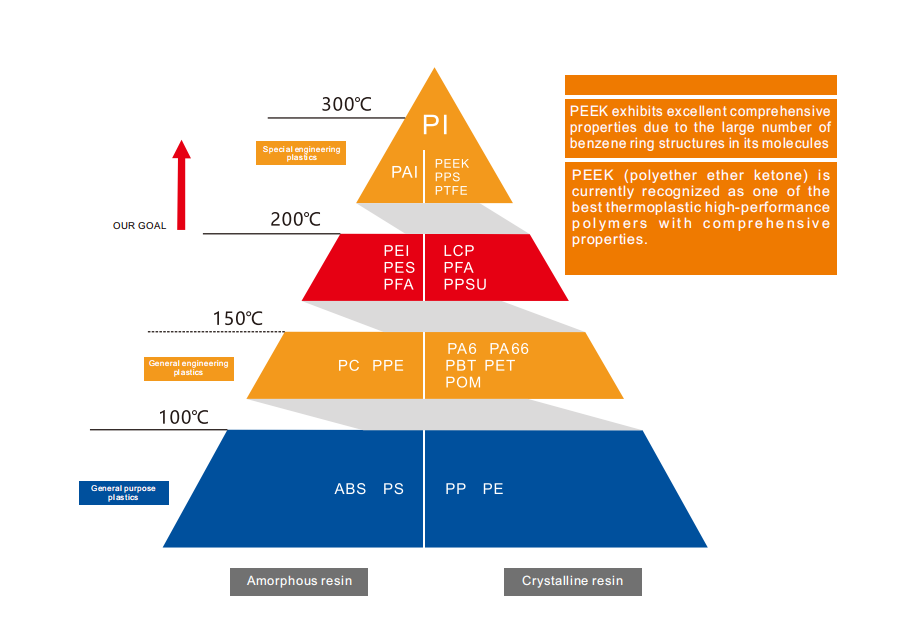

● PEEK material is almost the best among all the thermoplastic materials

In general, PEEK (polyetheretherketone) material can maintain good performance at low temperatures of -40 ℃.

At this temperature, its mechanical properties, such as tensile strength, bending strength, etc., may undergo certain changes, but it can still maintain good toughness and strength, without brittle fracture, and can function normally.

The glass transition temperature of PEEK resin is about 143 ℃, with a very high melting point of 343 ℃ and a thermal deformation temperature of 156 ° C.

The long-term use temperature can reach 260 ℃, and the short-term use temperature can even exceed 300 ℃. In high temperature environments, its performance deteriorates slowly, but it can maintain good strength, stiffness, and dimensional stability.

The testing of hot deformation temperature is conducted under specific loading conditions, mainly reflecting the temperature at which the material begins to undergo significant deformation under certain external forces and heating rates.

Taking the common hot deformation temperature testing standard ASTM D648 as an example, PEEK resin will show significant deformation at around 156 ° C under a load of 0.45MPa.

The long-term use temperature refers to the temperature at which the material can maintain stable performance and meet actual usage requirements for a long time under different environmental factors. The determination of this temperature is based on a large amount of experimental data, practical application experience, and long-term monitoring of material performance changes.

Heat deformation temperature increase:

Generally, PEEK reinforced with 30% fiberglass can reach a heat deformation temperature of over 315 ℃. Fiberglass itself has high thermal stability and is uniformly dispersed in the PEEK matrix, which limits the movement of PEEK molecular chains at high temperatures, allowing the material to withstand higher temperatures without significant deformation. For example, in automotive engine peripheral components, it can maintain stability under high temperature conditions.

Enhanced dimensional stability:

At high temperatures, the size change of glass fiber reinforced PEEK is smaller. The thermal expansion coefficient of fiberglass is different from that of PEEK matrix, which mutually restricts and reduces the overall thermal expansion coefficient of the material. In the manufacturing of precision instrument components, it can ensure the dimensional accuracy of the components and reduce the impact of temperature fluctuations on product performance.

Good mechanical properties maintained at high temperatures:

Compared to pure PEEK, fiberglass reinforced PEEK exhibits significant improvements in mechanical properties such as bending modulus at high temperatures, which can be increased several times to over 10000 MPa. Fiberglass plays a role in reinforcing the skeleton, sharing the load, and enabling the material to withstand significant external forces at high temperatures, ensuring the normal operation of the components.

Significant increase in hot deformation temperature:

After modification with carbon fiber, the hot deformation temperature of PEEK is further increased, which can meet the extremely high temperature performance requirements of application scenarios. For example, high-temperature cable sleeves in the electronics industry can withstand higher temperatures, ensuring safe operation of cables in high-temperature environments.

Thermal conductivity change:

Carbon fiber has good thermal conductivity, and adding carbon fiber reinforcement significantly improves the thermal conductivity of PEEK. In some electronic device components that require heat dissipation, it can quickly conduct heat, improve device heat dissipation efficiency, and ensure the stability of the device during high load operation.

Excellent mechanical performance at high temperatures:

PEEK with 20% carbon fiber added significantly improves strength and stiffness. In high temperature environments above 200 ℃, mechanical performance indicators such as tensile strength and bending strength are significantly improved compared to pure PEEK. In the aerospace field, it is used to manufacture engine covers, wings and other components that can still have sufficient strength and rigidity under extreme conditions such as high temperature and high pressure, ensuring the safety of aircraft.

Although polyetheretherketone (PEEK) is slightly inferior to polyimide (PI) in its long-term temperature resistance (continuous use temperature of 250 ℃ vs. 300 ℃+) its excellent thermoplastic processability is reshaping the application pattern of high-end engineering plastics.

As one of the few thermoplastic ultra-high performance polymers that can be molded by injection molding, peek can realize rapid melt processing in the range of 380-400 ℃, support diversified production processes such as extrusion and blow molding, and shorten the production cycle by more than 60% compared with the high-temperature sintering or complex post curing process required for pi materials.

This feature not only significantly reduces the manufacturing cost of precision parts, but also enables designers to freely realize innovative forms such as complex thin-walled structures and microporous arrays, showing unique value in aerospace connectors, medical implant injection molding and other fields that are demanding on both molding efficiency and structural accuracy.

When your project needs to achieve a strategic balance between high temperature tolerance and mass production feasibility, peek is providing an irreplaceable industrial solution.

To Achieve Lightweighting, Which Plastic Materials Can Replace Metals?

What Is The Difference between Carbon Fiber PEEK And Glass Fiber PEEK?

Why Choose PEEK Material As The Base Material for Anti-static Purposes

Why PEEK 3d Printing Fliaments Need To Choose High Flow Grade for Extrusion?

What Is The Difference between Carbon Fiber PEEK And Bearing Grade PEEK?