| density: | |

|---|---|

| Color: | |

| model: | |

| Material: | |

| thickness: | |

| Elongation at break: | |

| Availability: | |

PEEK-film

PRES

PEEK is easy to process into complex shapes, Suitable for ultra-thin designs, and meets the demands of mobile devices for miniaturization and high sound quality.

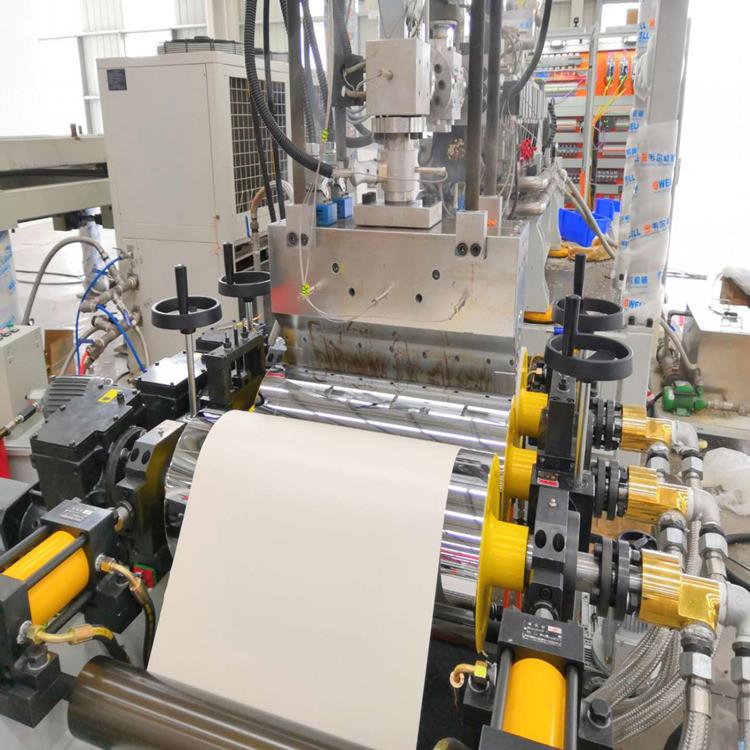

The PEEK film from PRES can reach 0.05mm.

PEEK film has extremely high fatigue strength and can maintain stable performance under high-frequency vibration and repeated deformation conditions. The speaker diaphragm made of PRESPEEK-990G can have a service life that is more than three times that of ordinary materials.

This is attributed to the high fatigue resistance and self-lubricating properties of PEEK material, which reduces the fatigue fracture or performance degradation of the material caused by long-term vibration

Black color pure PEEK resin film

Black PEEK film is a decorative grade film.

Its performance is exactly the same as that of natural-color films and is suitable for products that require a dark surface.

such as acoustic speakers and aviation insulation and soundproofing applications, etc

Nature color PEEK film

We are improving the process to produce thinner PEEK films and further expand the application range of PEEK films

PEEK film can maintain stable insulation performance even in high-temperature and high-frequency environments and is widely used as the insulation layer of equipment such as motors, generators, transformers, and power capacitors. Its low water absorption (superior to polyimide PI) enables it to maintain performance even in a humid environment. Meanwhile, its resistance to solder wire and radiation makes it suitable for complex processes in electronic manufacturing.

Ultra-thin PEEK films are used in the speaker diaphragms of devices such as smartphones and headphones. They enhance sound quality through high rigidity and low distortion characteristics, and support miniaturization and high output sound quality design.

As an insulating layer for high-frequency signal transmission, PEEK film is used for winding and carrier tape protection of printed circuit boards, meeting the requirements of low dust, low gas release and high purity in semiconductor manufacturing.

PEEK film is used to replace metal in manufacturing engine peripheral components, transmission system parts, etc., reducing weight and enhancing high-temperature resistance and fatigue resistance. For example, 44 components of a certain model in Europe use PEEK material instead of metal.

In aerospace, PEEK films are used in components such as aircraft pneumatic impellers and bearing sleeves, which can withstand high temperatures, radiation and chemical corrosion, while meeting the requirements of lightweight.

In chemical pumps, valves and other equipment, PEEK films are used as seals or coatings to resist the corrosion of acids, alkalis and organic solvents, thereby extending the service life of the equipment.

It is used for proton exchange membranes in fuel cells or separators in lithium batteries, taking advantage of its high-temperature resistance and chemical stability to enhance safety and efficiency (speculated application, extended based on chemical resistance).

To Achieve Lightweighting, Which Plastic Materials Can Replace Metals?

What Is The Difference between Carbon Fiber PEEK And Glass Fiber PEEK?

Why Choose PEEK Material As The Base Material for Anti-static Purposes

Why PEEK 3d Printing Fliaments Need To Choose High Flow Grade for Extrusion?

What Is The Difference between Carbon Fiber PEEK And Bearing Grade PEEK?