| diameter: | |

|---|---|

| weight: | |

| Color: | |

| Availability: | |

PEEK660G

PRES

High performance PEEK material is a 3D printed wire used for fuse deposition (FF/FDM) technology principles.

Can be exposed to various organic reagents and certain acidic and alkaline substances for a long time, solving the material needs of medical equipment, scientific research equipment, mechanical components, nuclear power plants, that emit radiation.

|  |  |  |  |  |

| High toughness | High temperature resistance | Stable Filament Diameter | No bubbles | Excellent electrical performance | warping resistance |

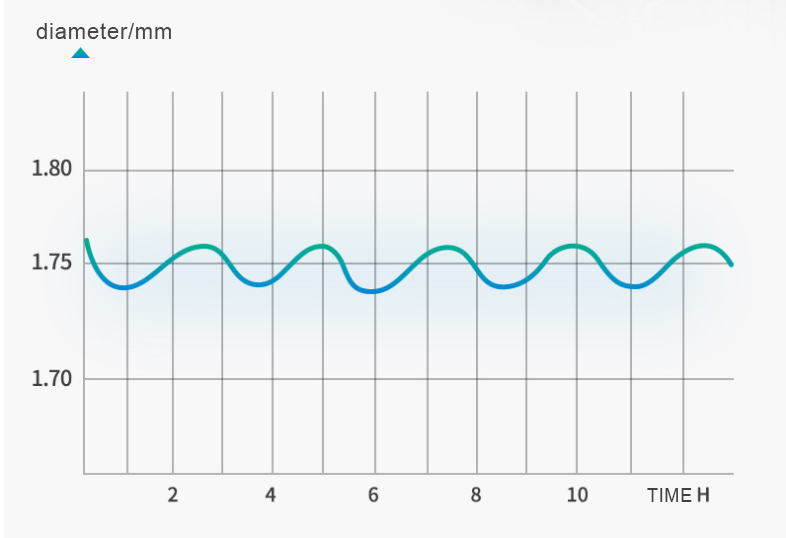

Stable Filament DiameterTolerance ±0.05mm

Uniform filament diameter, easy to use, excellent printing results, more stable extrusion

PEEK filament properties &PEEK printing parameters

| Parameter | Parameter Name | Parameter Value | Standard/Notes |

|---|---|---|---|

| PEEK printing parameters | Printing Temperature | 380-430℃ | |

| Heated Bed Temperature | 80-120℃ | ||

| Constant Temperature Chamber | 80-90℃ | ||

| Filament Diameter | 1.75+/-0.05mm | ||

| Density | 1.3g/cm³ | ||

| Glass Transition Temperature | 143℃ | ||

| PEEK printing filament performance | Tensile Strength | 70.4MPa | ASTMD638-14 |

| Tensile Rate | 28.5% | ASTMD638-14 | |

| Compression Modulus | 1.60GPA | ||

| Compression Strength | 55.8MPa | ||

| Flexural Strength | 81.9MPa | ||

| Operating Temperature Range | 46-230℃ |

PEEK 3D printing filament application

Automotive field:

PEEK has good mechanical processability, flame retardancy, wear resistance, corrosion resistance, low threshing degree and other characteristics. The rail transit equipment and automotive industry play a very important role in reducing their own weight, extending the service life of existing components, and optimizing component utilization.

PEEK has replaced some of the original metal components and has outstanding advantages in processing, making it easy to operate. At present, various high-performance gaskets, pump bodies, engine covers, gaskets, sealing rings, clutch gear rings and other related components in the car can be manufactured, as well as high and low voltage power transmission and transformation components.

Medical field:

Due to its ability to withstand repeated high-pressure sterilization, PEEK can be used in medical devices to manufacture endoscope parts, dental descaling devices, and more. In addition, due to the strength and low solubility of PEEK, it has been used in liquid chromatography columns, tubes, accessories, etc. for instrument analysis.

Moreover, due to its excellent compatibility with the human body, PEEK has gradually replaced traditional titanium metal as an artificial bone material in recent years.

Home appliance field:

PEEK has good wear resistance, self-lubricating properties, non toxicity, high temperature resistance, and low density. Compared with metal components, it can reduce noise, energy consumption, and extend service life.

To Achieve Lightweighting, Which Plastic Materials Can Replace Metals?

What Is The Difference between Carbon Fiber PEEK And Glass Fiber PEEK?

Why Choose PEEK Material As The Base Material for Anti-static Purposes

Why PEEK 3d Printing Fliaments Need To Choose High Flow Grade for Extrusion?

What Is The Difference between Carbon Fiber PEEK And Bearing Grade PEEK?