Views: 239 Author: Site Editor Publish Time: 2025-02-27 Origin: Site

Content Menu

● Distribution of mold product types

● Our advantages in PEEK mold design and injection molding

>> DFM

● How to get your customized product?

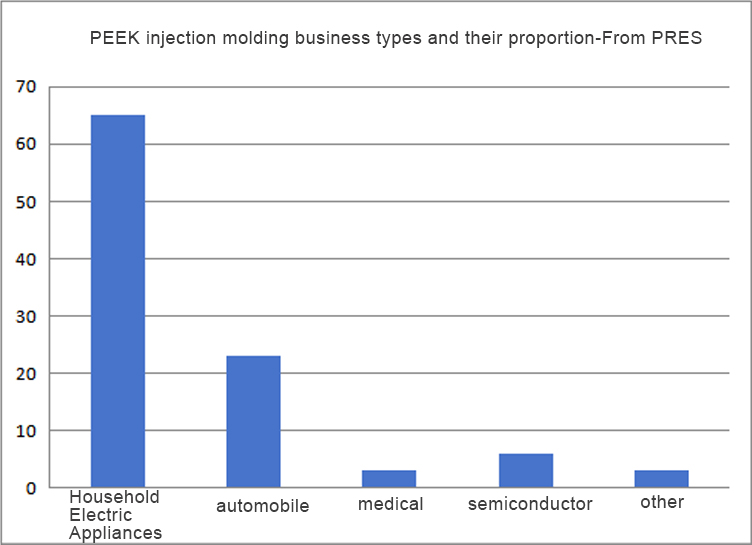

At present, the proportion of mold design and injection molding for PRES is as follows: household appliances account for 65%, automobiles account for 23%, medical products account for 3%, semiconductor account for 6%, and others account for 3%; Our automotive and medical businesses are growing rapidly now.

Complete 3D Mold Design in Pro-E

Standardization & Customization

Project Management

Early Supplier Involvement

Product Design capability plus on site mold design support

In House Mold-Flow simulation

Access to multiple CAD/CAM Software

Pro-E, Catia & Unigraphics

|  |

|  |

Detailed technical points, complete DFM report

Conduct feasibility analysis of molds for customer products and propose optimization solutions,

To avoid various problems caused by the product before mold making and improve the efficiency of mold making

Mold Flow Analysis (MFA) is a method that uses computer simulation technology to analyze the flow and molding process of plastics in molds.

Basic Principle:

Based on the physical principles and mathematical models of plastic molding, numerical calculation methods are used to discretize the mold cavity and the plastic melt into tiny units. By solving the mathematical equations, the distribution of physical quantities can be obtained to predict molding problems.

Main Analysis Content:

It includes filling analysis, packing analysis, cooling analysis, warpage analysis, fiber orientation analysis, etc., to predict various problems in the molding process.

Role in Product Design and Mold Manufacturing:

Optimize product design, discover and solve factors in structural design that are not conducive to molding in advance; optimize mold design, rationally design the gate, runner system, and cooling water channels; predict molding problems and improve the success rate of mold trial; optimize the molding process parameters, find the optimal combination of production parameters, and improve production efficiency and product quality stability.

|

充填时间(Fill time )(sec) | 1.63 | 充填是否平衡(The degree of balance) | ok |

是否有短射(Whether there is Short shot) | No | 是否有明显的迟滞(Whether there is clear hesitation) | No |

The advantages of fully 3D mold design are significant.

During the design process, the mold structure can be visually presented, making it easy to quickly modify and adjust, and achieving efficient collaborative design;

In terms of design quality, precise interference inspection can be carried out, mold structure can be optimized, and the molding process can be simulated realistically;

In terms of manufacturing and assembly, it can generate precise machining data, guide assembly and debugging, and reduce manufacturing costs;

At the document and management level, intuitive technical documents can be generated for easy data management and sharing, comprehensively improving the level of mold design, manufacturing, and management.

|  |  |

main steel (core and cavity ,slider , lifter for tooling) process the full-inspectionBy CMM.

The CMM measurement system plays a crucial role in mold manufacturing. It can measure the dimensions of various parts of the mold with high precision, accurately control the machining accuracy of key parts such as the cavity and core, and detect and correct machining errors in a timely manner.

In the assembly process, measurements are taken to ensure that each component is assembled properly, ensuring overall assembly accuracy. Moreover, it can meticulously inspect the surface contour and positional tolerances of molds, ensuring that mold manufacturing meets strict standards, improving mold quality, extending service life, and facilitating efficient production.

|  |  |

Our CNC machining centers have a wide range of equipment, covering various models from lightweight precision machining to heavy-duty powerful cutting.

High speed milling machining centers carve delicate and precise complex surfaces for mold manufacturing at extremely high speeds;

The large gantry machining center, with its spacious worktable and powerful power, can easily handle the machining tasks of large structural components, accurately milling and drilling, ensuring millimeter level accuracy.

There is also a turning milling composite machining center, which can complete various processes such as turning and milling in one clamping, greatly improving machining efficiency and accuracy, and fully meeting the diverse precision machining needs of various industries.

CNC department | MAKINO V80S- 5 Axis CNN | ||

|  | ||

CNC-Gantry GMF2715L | MAKINO F5 High Speed CNC | MAKINO F3 High Speed CNC | CNC—GUOSHENG CMV855S |

|  |  |  |

|  |  |

| injection molding production line | Mold warehouse | |

|  |  |

The main brands of injection molding machines produced by the company are Toshiba, Nippon Steel, and Mitsubishi from Japan. The machine position ranges from 100T to 1300T to meet the injection molding needs of customers with different product sizes.

These advanced injection molding machines are equipped with high-precision control systems that can accurately regulate injection pressure, speed, and temperature, ensuring the dimensional accuracy and appearance quality of plastic products. From precision electronic component casings to large automotive interior components, they can all be efficiently produced.

At the same time, our experienced technical team can optimize injection molding process parameters based on customer product characteristics, achieve cost reduction and efficiency improvement, provide customers with one-stop injection molding solutions, and help them stand out in the fierce market competition.

ITEM | MACHINE TON | MODEL | BRAND | Qty(set) | Screw dimension 螺杆直径 |

1 | 100T | 80MSG-40 | MITSUBISHI | 1 set | 36 |

2 | 150T | J150EII | JSW | 2 set | 46 |

3 | 160T | 160MSG-40 | MITSUBISHI | 1 set | 45 |

4 | 220T | IS-220GN-10A | TOSHIBA | 4 set | 45/45/45/50 |

5 | 220T | J220 | JSW | 1 set | 45 |

6 | 280T | IS-280GS | TOSHIBA | 2 set | 60 |

7 | 350T | J350TEⅢ | JSW | 8set | 66 |

8 | 450T | IS-450E-27Z | TOSHIBA | 1 set | 70 |

9 | 450T | J450 | JSW | 1 set | 84 |

10 | 550T | J550EIII | JSW | 2 set | 83 |

11 | 550T | 550MG | MITSUBISH | 2 set | 78 |

12 | 650T | 650MG | MITSUBISHI | 1 set | 90 |

13 | 850T | IS850 | TOSHIBA | 1 set | 100 |

13 | 1050 | 1050MG | MITSUBISHI | 1 set | 120 |

14 | 1300 | IS1300 | TOSHIBA | 1 set | 115 |

15 | 2K machine | 2 set | 45/115 | ||

totally | 31 set |

| Step | Description |

|---|---|

| 1. Receive Order | - The customer submits an order through the quotation page, providing project requirements and details. - The service provider reviews the project details, evaluates feasibility, and confirms cooperation with the customer. |

| 2. Design Feasibility Analysis (DFM) | - Conduct DFM analysis to ensure the design is suitable for manufacturing, simplifying the production process and improving efficiency. - Adjust the design as needed based on DFM analysis to ensure manufacturability and cost-effectiveness. |

| 3. Reconfirmation | - The customer reviews and approves the final design. - The customer officially places the production order, confirming the start of the manufacturing phase. |

| 4. Manufacturing | - Produce the required molds based on the approved design. - Begin the injection molding process to manufacture high-quality parts. |

| 5. Quality Control and Adjustments | - Perform thorough quality inspections on each produced part to ensure it meets the customer's requirements. - Make immediate adjustments if issues are found to ensure the final product meets the expected quality standards. |

| 6. Delivery | - Package all parts that pass quality inspection for shipment. - Deliver the order to the customer, completing the custom process. |

To Achieve Lightweighting, Which Plastic Materials Can Replace Metals?

What Is The Difference between Carbon Fiber PEEK And Glass Fiber PEEK?

Why Choose PEEK Material As The Base Material for Anti-static Purposes

Why PEEK 3d Printing Fliaments Need To Choose High Flow Grade for Extrusion?

What Is The Difference between Carbon Fiber PEEK And Bearing Grade PEEK?