| Color: | |

|---|---|

| Material: | |

| characteristic: | |

| Availability: | |

PEEK-990CA30

PRES

| material | model | OD(mm) | ID(mm) | length(mm) | |

|---|---|---|---|---|---|

| PEEK resin-unfilled PEEK | PEEK–990G | 1~350 | 1~350 | 1000 |

| Glass fiber reinforced PEEK | PEEK–990GF30 | 10~300 | 10~300 | 1000 | |

| Carbon fiber reinforced PEEK | PEEK–990CA30 | 10~300 | 10~300 | 1000 |

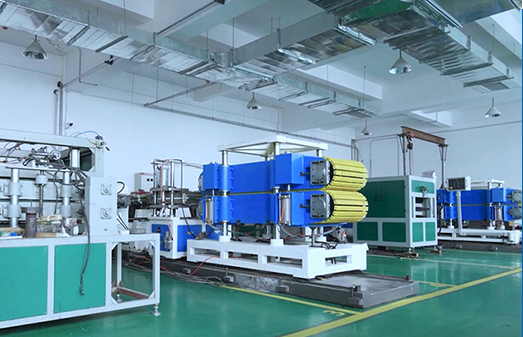

Introducing advanced continuous extrusion production lines for profiles, improving the production efficiency of PEEK profiles in China, reducing costs, and having a large inventory of nearly a hundred specifications of PEEK pipe extrusion molds available .

Introducing advanced continuous extrusion production lines for profiles, improving the production efficiency of PEEK profiles in China, reducing costs, and having a large inventory of nearly a hundred specifications of PEEK pipe extrusion molds available .

The PEEK tube produced by continuous extrusion process solves the technical problems of limited product height in compression molding process and easy internal shrinkage holes in injection molding process, while reducing material loss and machining costs.

It can be customized for non-standard cutting according to customer requirements

Mechanical Data | standard | condition | unit | value |

| Tensile Strength | ISO 527 | Yield, 23℃ | MPa | 260 |

| Tensile Elongation | ISO 527 | Break, 23℃ | % | 1.7 |

| Flexural Strength | ISO 178 | Yield, 23℃ | MPa | 380 |

| Flexural Modulus | ISO 178 | 23℃ | GPa | 23 |

| Compressive Strength | ISO 604 | 23℃ | MPa | 300 |

| Charpy Impact Strength | ISO 179/1eA | Notched | kJ m−2 | 7 |

| ISO 179/IU | Unnotched | kJ m−2 | 45 | |

| Izod Impact Strength | ISO 180/A | Notched | kJ m−2 | 9 |

| ISO 180/U | Unnotched | kJ m−2 | 45 | |

| Mould Shrinkage | ISO 294-4 | Along Flow | % | 0.1 |

| Across Flow | % | 0.5 | ||

| Thermal Data | standard | condition | unit | value |

| Melting Point | ISO 11357 | - | ℃ | 343 |

| Glass Transition (Tg) | ISO 11357 | Onset | ℃ | 143 |

| Special Heat Capacity | DSC | 23℃ | kJ kg−1−1℃−1−1 | 2.2 |

| Coefficient of Thermal Expansion | ISO 11359 | Along flow below Tg | ppm K−1−1 | 45 |

| Along flow above Tg | ppm K−1−1 | - | ||

| Heat Deflection Temperature | ISO 75 | 1.8 Mpa | ℃ | 152 |

| Thermal Conductivity | ISO 22007-4 | 23℃ | W m−1−1K−1−1 | 0.29 |

To Achieve Lightweighting, Which Plastic Materials Can Replace Metals?

What Is The Difference between Carbon Fiber PEEK And Glass Fiber PEEK?

Why Choose PEEK Material As The Base Material for Anti-static Purposes

Why PEEK 3d Printing Fliaments Need To Choose High Flow Grade for Extrusion?

What Is The Difference between Carbon Fiber PEEK And Bearing Grade PEEK?