| Availability: | |

|---|---|

PEEK-uav

PRES

|Material Choice

The bending strength and modulus of PEEK material reinforced with carbon fiber are very high. Taking the PEEK880CA30 of PRES as an example, the bending strength reaches 370Mpa and the bending modulus reaches 22Gpa.

Drones are often used outdoors and are often exposed to ultraviolet radiation. Common materials such as ABS, PP, PE, etc. will oxidize and become brittle after being exposed to ultraviolet radiation. The drone shell made of these materials is prone to performance degradation after prolonged exposure to sunlight, resulting in the loss of protection for the core components of the drone.

Carbon fiber reinforced PEEK material has the characteristic of wear resistance. When it comes into contact with dust in the air during rapid movement, it is not easy to wear and scratch, and can still maintain a good surface after long-term use.

The outstanding feature of PEEK material lies in its excellent high temperature resistance, corrosion resistance, and radiation resistance, which enables it to work in harsh environments for a long time while maintaining a high level of performance and performing some special tasks.

|Other Material Choice

The performance of these two materials is lower than that of PEEK material, but their cost is lower, and suitable materials can be selected according to cost and performance requirements

PC/ABS alloy

PC/ABS alloy combines the advantages of PC and ABS, and has excellent comprehensive performance, including high strength, high toughness, and good processability. This material is suitable for drone casings that require high strength and weather resistance

PA6 material

PA6 plastic has high strength, high modulus, and good wear resistance, and is commonly used in the manufacture of propellers and support structures. Its low warpage and high toughness make it perform well in plastic drones, especially in components that require high strength and durability

|Advantage

Free modification of 3D drawings during the cooperation period

High precision: tolerance can reach to 0.03mm

Molds require regular maintenance to keep the accuracy and stability of the product

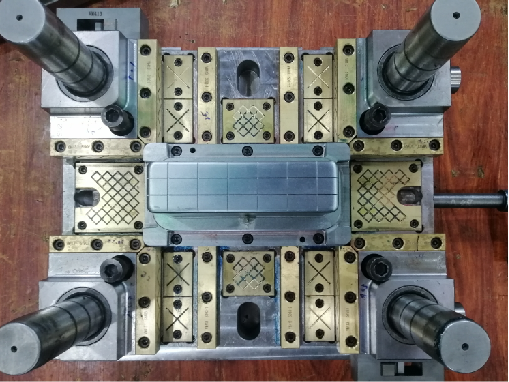

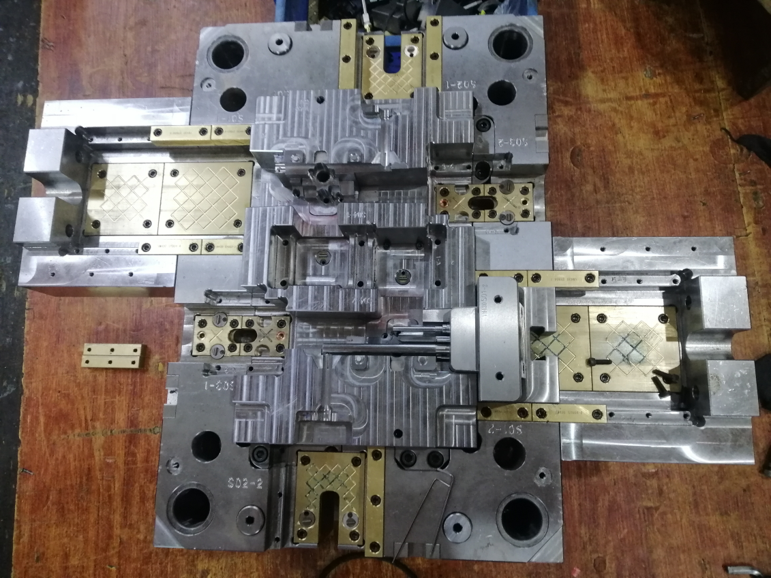

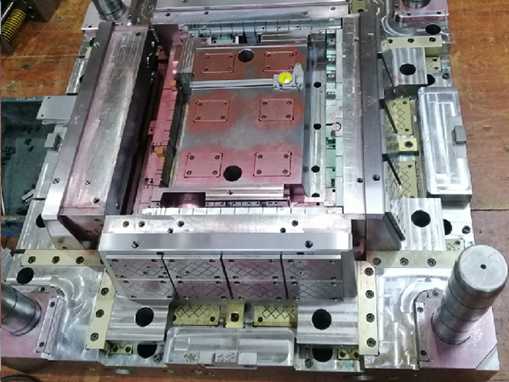

| Mold making Video

PRES has 15+ years of experience in mold manufacturing and injection molding,we have 18 mold processing equipment and 23 injection molding machines, capable of adapting to manufacturing and production of different sizes

|

Comment & FAQ

1. What drone accessories can you make?

A: Drone paddles, drone shells, drone support frames, camera fixtures, etc., or your unique requirements.

2. Can I do non-standard customization without drawings?

A: Yes, we can help you design and charge a design fee, but after production, the design fee can be deducted from the product cost, in other words, free design!

3. what is the MOQ?

A: The MOQ is 500-1000 pcs,But this is not absolute, please feel free to ask us for a quote.

|

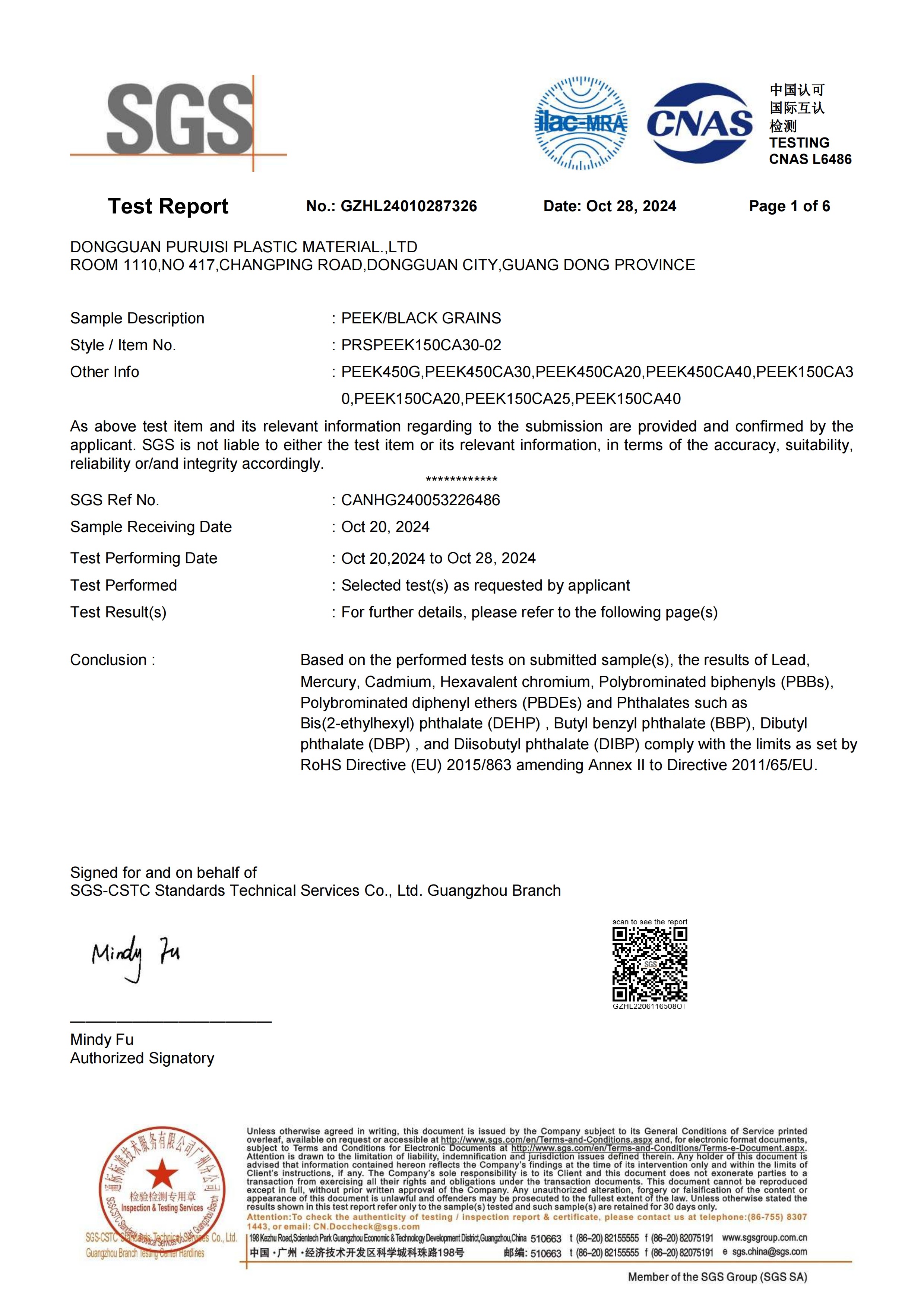

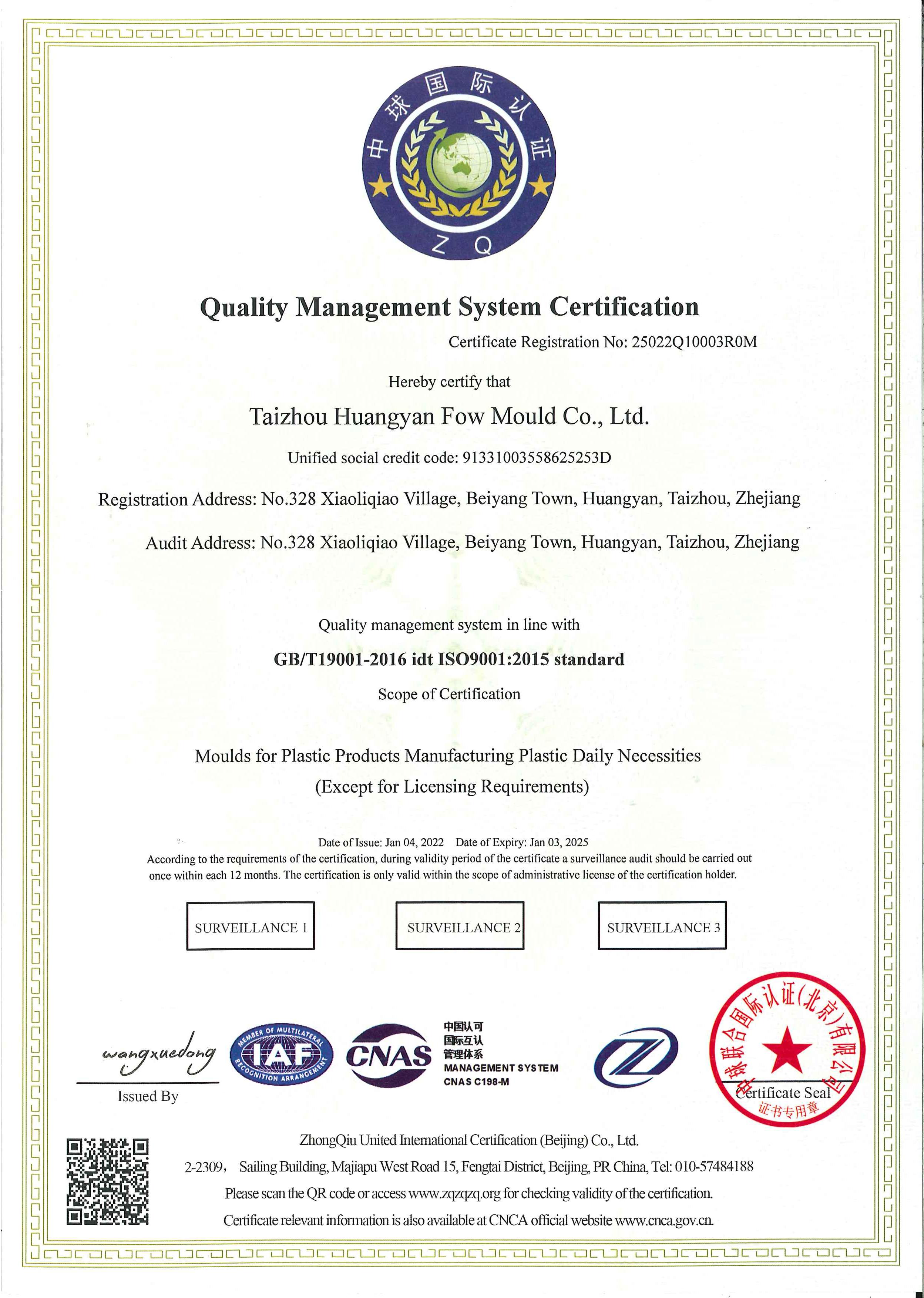

Certifications

SGS Certification of PEEKCA30 material

MSDS Certification of PEEKCA30 material

MSDS Certification of PEEKCA30 material

Environmental Quality Certification of PRES company

To Achieve Lightweighting, Which Plastic Materials Can Replace Metals?

What Is The Difference between Carbon Fiber PEEK And Glass Fiber PEEK?

Why Choose PEEK Material As The Base Material for Anti-static Purposes

Why PEEK 3d Printing Fliaments Need To Choose High Flow Grade for Extrusion?

What Is The Difference between Carbon Fiber PEEK And Bearing Grade PEEK?