| Size: | |

|---|---|

| Availability: | |

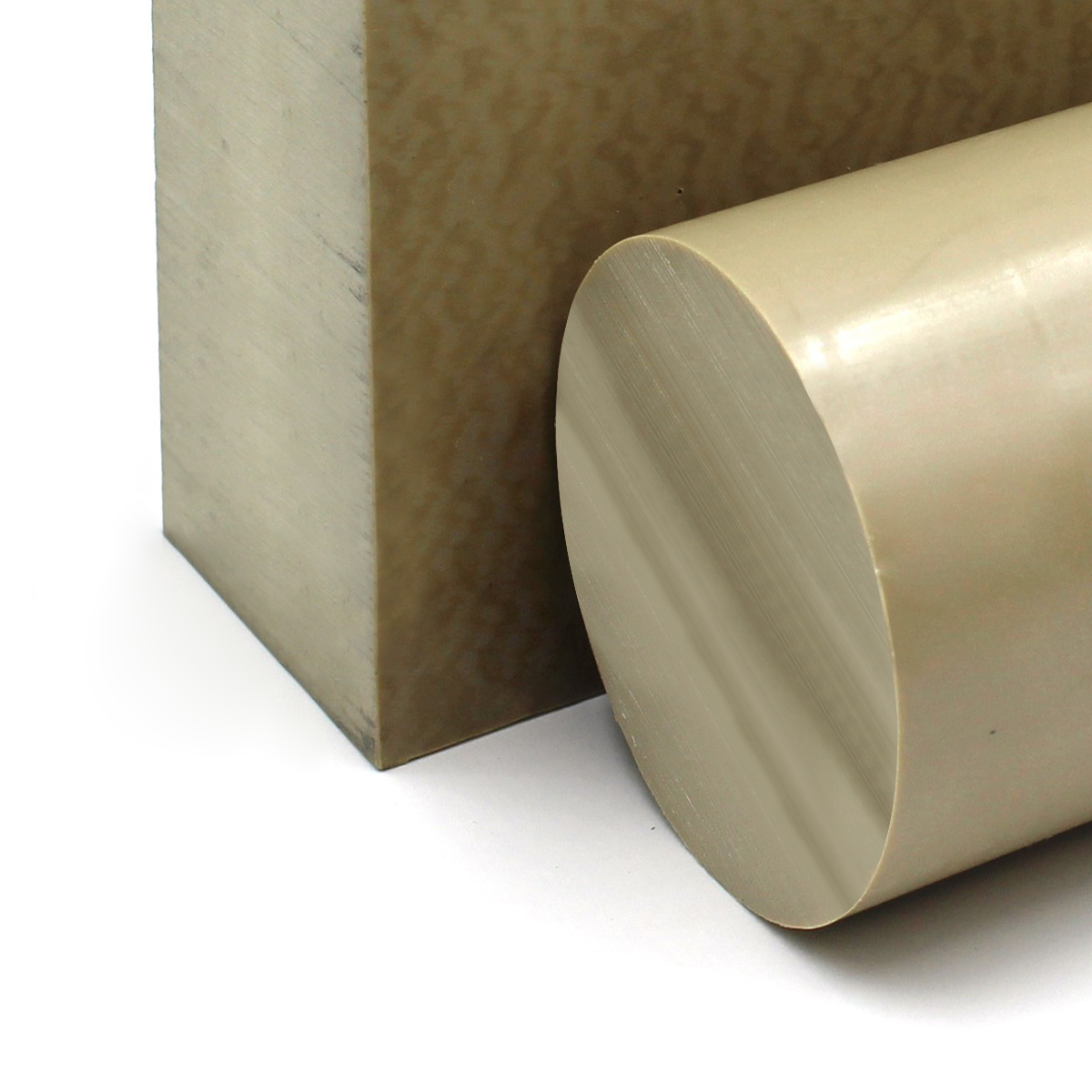

PEEK990G

PRES

The thickness of PEEK boards produced by PRESS is usually 6-120mm, and PEEK resin boards have the most sufficient size.

| Material | thickness | |

| PEEK resin | 1mm,2mm,3mm,4mm,5mm,6mm | 6-120mm |

| Glass fiber reinforced PEEK | 6mm | 6-50mm |

| carbon fiber reinforced PEEK | 6mm | 6-50mm |

| Bearing grade PEEK | 6mm | 6-50mm |

Due to the addition of fibers, PEEK boards that are too thin or too thick can result in uneven filling of internal fibers.

When producing oversized PEEK sheets, the cooling rate of the surface and interior PEEK is different. The surface cooling rate is fast, the crystallization rate is fast, the interior cooling rate is slow, the crystallization rate is slow, and it is easy to generate internal forces, warp, and uneven mechanical properties.

However, PRES has extensive experience in producing large-sized profiles and significantly reduces internal stress by optimizing production processes and post-processing.

PEEK resin sheet

PEEK resin sheet PEEK resin does not require fiber filling and does not require consideration of fiber distribution during production. Therefore, PEEK resin sheets can be easily produced in larger or smaller sizes.

Glass fiber reinforced PEEK plate

PEEK reinforced with fiberglass significantly improves its impact resistance, rigidity, and dimensional stability.

As an ideal material for structural components, we can produce PEEK-GF30 boards with special sizes for you

carbon fiber reinforced PEEK sheet

Among numerous PEEK modified materials, CF-PEEK has the highest usage temperature and modulus. In addition, it also has excellent wear resistance, low density, and low shrinkage rate.

In order to expand the application of CF-PEEK boards, PRES can produce special sized CF-PEEK boards according to customer needs.

The following sizes are commonly used and have sufficient inventory. They can be cut and quickly shipped according to your needs.

If you cannot find the size you need, you can contact us for customization.

厚度 MM Thickness | PEEK-Resin | PEEK-ESD | PEEK-GF30 | ||||

| 公差 MM Tolerance | 密度 KG/M⊃3; Density | 重量 KG/M Weight | 密度 KG/M⊃3; Density | 重量 KG/M Weight | 密度 KG/M⊃3; Density | 重量 KG/M Weight | |

| 6 | +0.2-+0.7 | 1.3 | 6.4 | 1.4 | 6.9 | 1.51 | 7.4 |

| 8 | +0.2-+0.7 | 1.3 | 8.8 | 1.4 | 9.4 | 1.51 | 10.1 |

| 10 | +0.2-+1.2 | 1.3 | 11 | 1.4 | 11.8 | 1.51 | 12.7 |

| 12 | +0.3-+1.5 | 1.3 | 12.6 | 1.4 | 13.5 | 1.51 | 14.5 |

| 15 | +0.3-+1.5 | 1.3 | 15.6 | 1.4 | 16.8 | 1.51 | 18.1 |

| 17 | +0.3-+1.5 | 1.3 | 17.6 | 1.4 | 18.9 | 1.51 | 20.4 |

| 20 | +0.3-+1.5 | 1.3 | 20.6 | 1.4 | 22.3 | 1.51 | 23.9 |

| 25 | +0.3-+1.5 | 1.3 | 25.8 | 1.4 | 27.7 | 1.51 | 29.9 |

| 30 | +0.5-+2.5 | 1.3 | 31.6 | 1.4 | 34.1 | 1.51 | 36.7 |

| 35 | +0.5-+2.5 | 1.3 | 36.1 | 1.4 | 38.6 | 1.51 | 41.6 |

| 40 | +0.5-+2.5 | 1.3 | 40.9 | 1.4 | 44.2 | 1.51 | 47.6 |

| 45 | +0.5-+2.5 | 1.3 | 46.2 | 1.4 | 49.5 | 1.51 | 53.4 |

| 50 | +0.5-+2.5 | 1.3 | 51.2 | 1.4 | 55.2 | 1.51 | 59.5 |

| 60 | +0.5-+3.5 | 1.3 | 61.2 | ||||

| 80 | +0.5-+5.0 | 1.3 | 80.1 | ||||

| 100 | +0.5-+5.0 | 1.3 | 102.9 | ||||

| 120 | +0.5-+5.0 | 1.3 | 121.9 | ||||

Click here to edit your content.

A:Click here to edit your content.

A:Click here to edit your content.

To Achieve Lightweighting, Which Plastic Materials Can Replace Metals?

What Is The Difference between Carbon Fiber PEEK And Glass Fiber PEEK?

Why Choose PEEK Material As The Base Material for Anti-static Purposes

Why PEEK 3d Printing Fliaments Need To Choose High Flow Grade for Extrusion?

What Is The Difference between Carbon Fiber PEEK And Bearing Grade PEEK?